It is well recognised and documented that we all need to “play our part” in reducing our impact on the environment. Dartford Composites Ltd, a specialist manufacturer of high quality GRP and GRP(ph) fire retardant and specialist components for the rail industry sector, is doing just that.

Established over 30 years, during this time the company has built an understanding of the rail & tram industry and a reputation of working with the customer to respond in a timely and cost effective manner.

Ruth Silvester, Sales and Marketing Director, has written the article below about how the company can help organisations become greener.

“More customers are actively considering the impact of their actions in their normal daily activities. By moving from a replacement approach to a refurbishment mindset leads to a substantial reduction in harmful emissions. Dartford Composites Ltd can assist you in making this transition as simple as possible.

Dartford Composites specialist refurbishment capability means that we are in a position to assist and support you in reaching your objectives by refurbishing items that would ordinarily simply be sent to landfill and replaced.

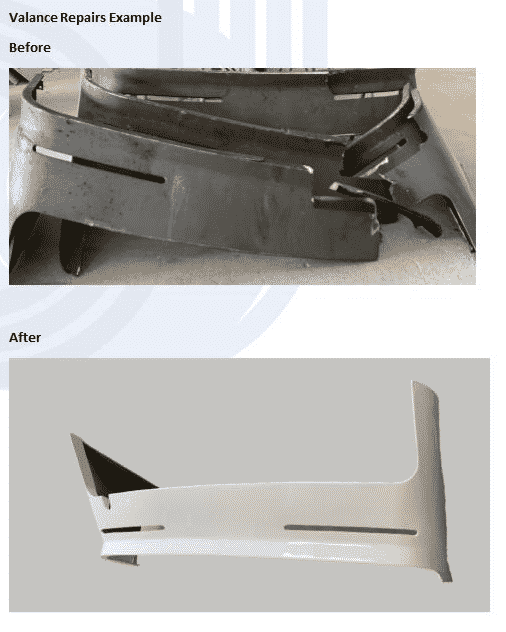

Be it in respect of “one off” items e.g., a baby change unit or a valance or in respect of supporting refurbishing items for a fleet refresh we work with you to support efficiently refurbishing items that would ordinarily go to landfill giving you both a more cost-effective solution to simply replacing with “new” and also enabling you to reuse items thus reducing your carbon footprint and assisting you in achieving your carbon reduction targets.

The rail industry faces additional challenges in reducing its carbon footprint. Due to the required fire rating only “virgin” material can be used in most manufacturing processes. Recycled material cannot be utilised as the fire rating will become void. The process of refurbishing the original component instead of replacement maintains the fire rating and provides visual appeal and extended lifespan desired by the customer.

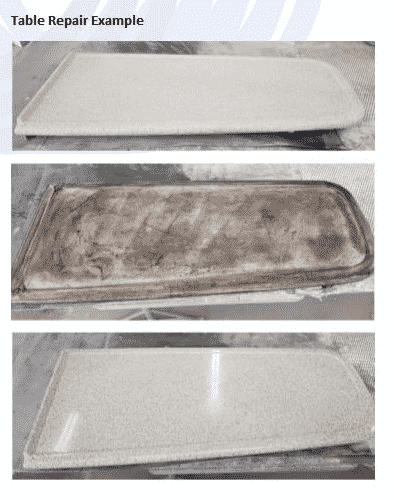

An example of a recent refurbishment project we completed was the refurbishment of 600 tabletops. The average weight per table was 18kg. This saved nearly 11 tons of raw material demand for replacement items, and 11 tons of landfill.

The Key Services

• Refurbishment assessment services – If you send through pictures of your damaged components, we will be able to review and supply recommendations in respect of suitable refurbishment processes.

• Reverse engineering – if you don’t have access to the drawings of the original items we can often “reverse” engineer items from an existing item to enable us to complete small production runs reducing the cost of full retooling if you require a short production run of new items where you need additional items and you don’t have the original items to refurbish or repair.

• Project Support – e.g. refurbishment of a full fleet of items to enable reusage e.g. tabletops and pantograph panels.

• Bespoke refurbishment services – including single items e.g. baby change units, skirts and valances.

• Our onsite repairs and refurbishment services include impact damage to train exteriors, interior damage repair including accidental damage and specialist processes to remove graffiti.

The Benefits

• Environmental Saving, refurbishment enables you to reduce your carbon footprint by reducing the number of items you send to landfill.

• Reduces the demand on raw materials for new components – refurbishment uses, on average, 85% less raw materials and resources than new manufacture.

• Cost Saving – Refurbishment is more cost effective than procurement of new replacement items.

• Time saving the lead time to complete refurbishment of items is less than to produce new particularly if you are required to go back to your OEM.

• We are a UK based firm utilising over 75% local suppliers in our supply chain – this gives us flexibility to adapt to support you in respect of urgent requirements.

• Fully documented processes- We can provide evidential support not just of the conformity of our products to the correct specific and standard, but also of the quantity of raw materials used in the repair of your product to assist you with any documentary evidence you require of how you have achieved your sustainability targets and for audit purposes including raw material batch codes.”

Visit www.dartfordcomposites.co.uk for more details.

Photo credit: Dartford Composites Ltd

0113 2082620

0113 2082620 info@railbusinessdaily.com

info@railbusinessdaily.com 15 Mariner Court, Wakefield WF4 3FL

15 Mariner Court, Wakefield WF4 3FL