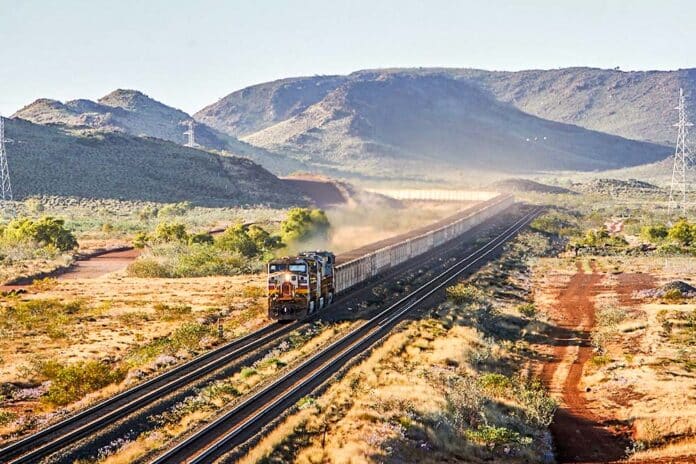

Hitachi Rail and Rio Tinto have marked another significant AutoHaul milestone with the commissioning of the autonomous rail transport system for the new Gudai-Darri iron ore mine in Western Australia’s Pilbara.

The greenfield mine development has involved the construction of a 166-kilometre rail spur to connect the new mine to Rio Tinto’s existing AutoHaul rail network in the region.

The world’s first fully automated heavy-haul, long-distance rail system, AutoHaul enables 220 trains, which are monitored remotely from an operations centre in Perth, to travel safely and efficiently across more than 1,866 kilometres of track from mines to ports – without the need for onboard drivers.

As the technical lead behind AutoHaul’s development, Hitachi Rail has provided the systems and software to connect the new section of rail for Gudai-Darri. This has included onboard and control centre technology, trackside equipment, radio base stations, and automatic train operation (ATO) interface software for locomotive control, level crossing safety and location tracking.

All systems and software are now operational following the first production test run and subsequent successful system commissioning.

Hitachi Rail Australia Senior Director Roslyn Stuart, said: “The Gudai-Darri AutoHaul network expansion project is a natural extension of Hitachi Rail’s long-term collaboration to deliver innovative rail transport solutions for Rio Tinto. The project has seen Hitachi Rail and the Rio Tinto AutoHaul team deliver another ‘first’, with back-to-back loading (high performing automated train loading) to be introduced on the Gudai-Darri mine rail loop.”

Rio Tinto operates the world’s largest integrated portfolio of iron ore assets and has a tangible commitment towards net-zero carbon emissions. The Gudai-Darri mine will also deploy autonomous haul trucks, fully autonomous water trucks and autonomous training solutions, and will be partially powered by a 34 megawatt photovoltaic solar farm solar plant.

Hitachi Rail is a world leader in autonomous and signalling technology and recently, also in Australia, began a major contract to install innovative technology to automate elements of Queensland’s New Generation Rail (NGR) fleet. The AU$107m contract will see Hitachi Rail install Automatic Train Operation over European Train Control System Level 2 technology on all NGR trains.

Thursday, April 25, 2024

0113 2082620

0113 2082620 info@railbusinessdaily.com

info@railbusinessdaily.com 15 Mariner Court, Wakefield WF4 3FL

15 Mariner Court, Wakefield WF4 3FL