Innovation and ongoing equipment development have long been at the heart of the scaffolding and access industry. With well-established benefits across the rail industry, Sean Pike, UK Managing Director of Layher Ltd., believes all parties have a key role to play in ensuring key objectives in this context are realised.

“All manufacturers of scaffolding products strive towards the same goals,” he says. “Maximising installation simplicity and efficiency – which have a direct bearing on competitiveness and profitability – and, of course, ensuring safety is optimised, have always been vital areas in which contractors have looked towards their suppliers to help deliver end-user needs.”

He believes that the industry cannot stand still in either case and there is thus a constant drive towards developing systems of scaffolding, access and weather protection that bring about improved performance.

At the heart of this scenario is innovation. Yet while it may be manufacturers who introduce new methods and equipment, it is so often the contracting sector that provides the inspiration. Installers of scaffolding, access and weather-protection equipment are invariably best placed to identify areas where specific challenges exist and, the rail sector is no exception. “There is no substitute for direct feedback from those ‘in the field’ so by working closely with the manufacturing sector, solutions can often best be created,” continues Sean Pike.

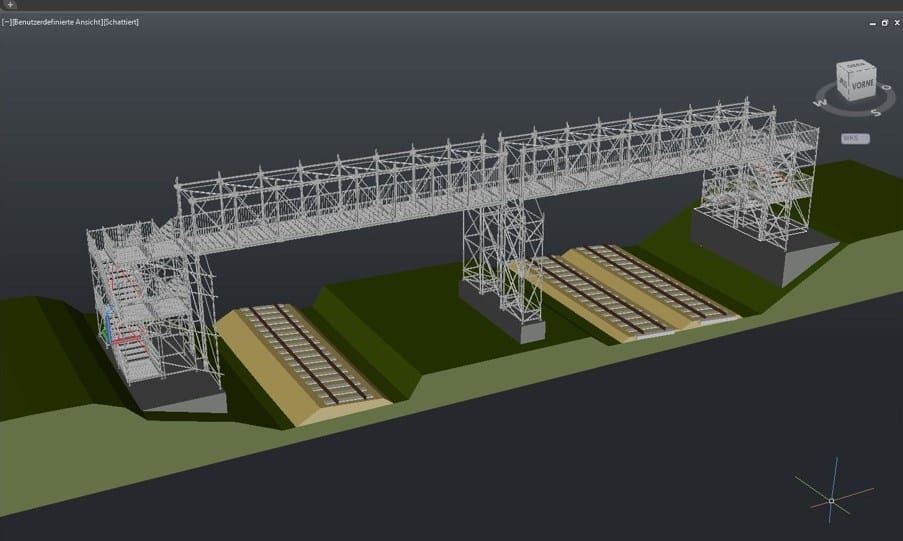

A range of examples can be noted where this principle has brought about clear-cut benefits. Not only is there a greater choice of specific components available today to meet a vast range of installation needs – Layher’s choice of temporary bridging systems is a case in point – but other key areas, such as project design, also bring new opportunities.

Computer-aided systems – such as the Layher Scaffold Information Modelling (SIM) software – underline this point. With on-screen or virtual visualisation capability that not only helps optimise installation efficiency by, for example, identifying potential clash areas, they also impact directly on the accurate identification of material needs.

Yet while close links between contractor and manufacturer often create a path towards innovations that improve efficiency, it is in the area of safety that, perhaps, the most important benefits can be seen.

“From optimised methods of construction where safe erection is built into product design, such as the Layher rosette connection system, to help with ensuring site delivery and storage procedures follow appropriate guidelines – all are central to safe operating procedures,” adds Sean. “Importantly, these have so often been brought about through co-operation between all relevant parties.”

The development of lightweight components is clearly under the spotlight in this context. The availability of high tensile steel has enabled manufacturers to maintain or even increase the strength of their products while, at the same time, reducing their weight. Layher’s Allround Lightweight Scaffolding, for example, has a direct bearing on physical handling to the extent that it can make a positive contribution to reducing the risk of musculoskeletal disorders. Moreover, lighter weight can often mean less bulk with a beneficial impact on transport and storage on site – benefits which need little explanation in the rail industry where trackside space is so often limited.

If inspiration and invention go hand in glove, then the scaffolding industry has much of which it can be proud. When the view is taken that manufacturers and contractors are, in effect, part of the same team, then the route for ever greater innovation is well founded. “As a consequence, the resulting steps towards better site efficiency and safety that can be readily identified today, point towards even greater benefits in the future,” concludes Sean.

Full details of the Layher range of equipment and services can be found via email to info@layher.co.uk, calling 01462 475100 or by visiting www.layher.co.uk.

Photo credit: Layher

0113 2082620

0113 2082620 info@railbusinessdaily.com

info@railbusinessdaily.com 15 Mariner Court, Wakefield WF4 3FL

15 Mariner Court, Wakefield WF4 3FL