Speaking to Rail Business Daily, Christopher Grosvenor, BIM lead for Spencer Group, explains how modelling can make engineering projects smoother, smarter and more cost effective.

BIM (Building Information Modelling) has the potential to transform engineering projects, making quality assurance easier, designs more collaborative, and sites safer. While, for many businesses, it is currently a ‘nice-to-have’, this capability needs to become the norm.

Contrary to the perceived ‘when time and budget allow’, a mature BIM strategy is indeed a proven time and money saver. BIM technology is now affordable and readily available. At Spencer Group, we believe that every project should benefit from it. A quality model, coupled with a consistent information structure, provides the best foundation for success.

A solid BIM foundation

Over the last year, Spencer Group has introduced project collaboration software ProjectWise as part of its wider BIM strategy. The tool quickly proved transformative, enabling team members to make small-but-impactful changes, free-up information, and do more in less time.

Something as simple as standardising the way documents are named has made a real difference. This process has enabled Spencer Group’s team to automate trackers and registers, and to gain a better overview of projects; it requires discipline and patience, but the payoff is significant.

We are already planning to build on our platform and have developed exciting new tools – like the capability to automatically synchronise ProjectWise with Spencer Group’s bespoke email and document control system. This will save valuable time, particularly for Spencer Group’s document control team; new documents no longer need to be registered, while material that has already been registered will become more comprehensive.

We will also be able to improve the system, tailoring it to the documents we produce – which, in turn, should make it more user-friendly.

Indeed, when it comes to BIM, laying the groundwork thoroughly and consistently unlocks benefits for everyone, and allows businesses to build on their capabilities in future.

Building our BIM capabilities

With this foundation in place, we plan to develop our own BIM capabilities further, pushing the use of full project models. Over the next 12 months, we’ll be encouraging all our teams to rely on models – whether that’s Design for drawing production, Site for task briefings, or Marketing for visualisations. Indeed, whatever the purpose, every team should be using the same model with the same information.

This, too, should be the goal of any organisation looking to harness the true potential of BIM. Ensuring that project information is stored and accessed in the same place facilitates collaboration, improves coordination and mitigates risk.

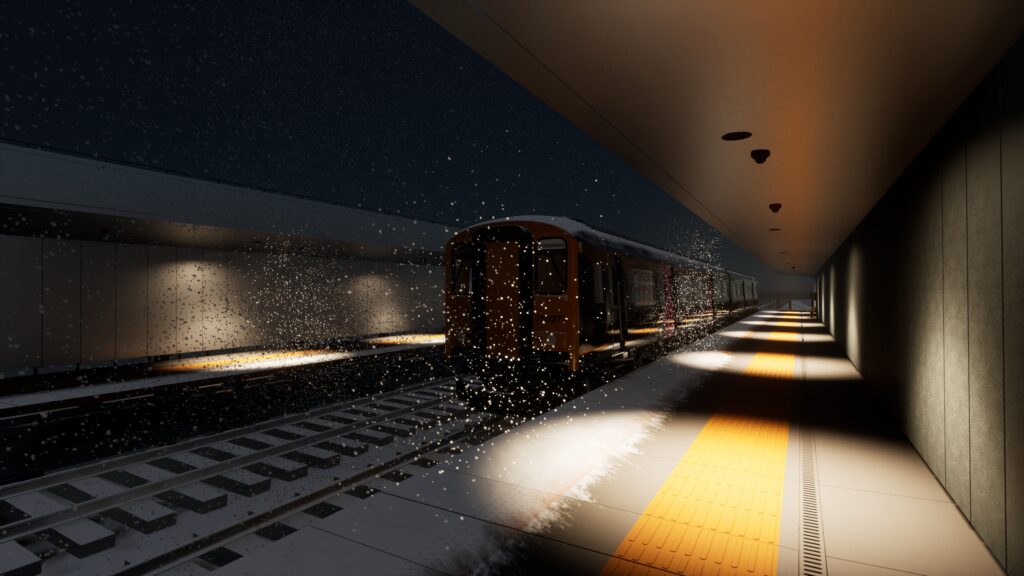

BIM can also help teams to explore and plan for a range of scenarios. Spencer Group recently began construction of the new White Rose Railway Station in Leeds and is using 3D models to explore signal sighting directly from the train cab, at night and in snow.

This kind of capability might sound futuristic – but going forward, it will become the norm.

Building a model is not just for new stuff either, the importance of starting from the right place is critical for the success of any project. We realise that investing in an accurate survey from day one will pay dividends throughout the project, and have developed a technique for building a data rich model from laser scans. It was only a few years ago that laser scans were considered a luxury, now are a standard form of survey, from which Spencer Group are again pushing the envelope.

Doing this provides the perfect backdrop to project planning, from design to logistics to construction, providing the correct environment to plan an entire project off site in an office is priceless when it comes to safety, improves efficiencies during the construction process, and experimenting with different materials cuts emissions for all of us.

The potential of modelling

Our well-established teams have been producing models for some time. Historically, they have been used exclusively for the creation of drawings, but we are now going to unlock their full potential.

This will involve sharing our models with a wider Spencer Group audience. We plan to make them available online, allowing users to take measurements, raise issues, cut through objects, and gain a clearer understanding of projects, all at the push of a button.

Just as introducing a consistent name structure has had significant benefits, so too will adopting a consistent modelling technique. Indeed, we believe that it will help Spencer Group to become a BIM leader, as well as opening the door to other capabilities – from augmented reality to the use of 3D printed components onsite.

This technology is no longer the stuff of science fiction, but readily accessible and affordable. Used properly – and with a quality model with a consistent information structure at its heart – it will help businesses to become quicker, smarter, more reliable and cost-effective.

0113 2082620

0113 2082620 info@railbusinessdaily.com

info@railbusinessdaily.com 15 Mariner Court, Wakefield WF4 3FL

15 Mariner Court, Wakefield WF4 3FL